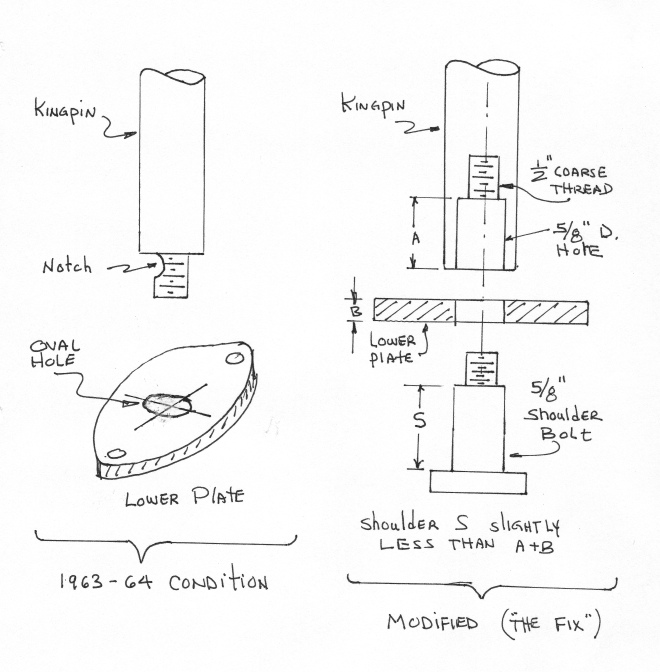

During the 1963-64 Major Rebuild, the stud on the bottom of the kingpin was found to be badly worn from lateral contact with the lower plate, and the hole in the plate was oval shaped (see sketch). The part of the stud in contact with the plate was threaded, which amplified the wear. New Morgan kingpins were purchased and modified. The stud was cut off and replaced with a hole that was drilled and tapped for a 5/8 inch diam. shoulder bolt. A new lower plate with a 5/8 inch hole was also made. The hole in the kingpin was drilled to a depth that slightly exceeded the length of the shoulder part of the bolt, so it would not bottom out (see sketch). The shoulder bolt head was drilled for safety wire.

The location of the hole in the lower plate affects the Camber and the Kingpin Inclination Angle (KPI). A few plates have been fabricated since 1963, and those now in the car provide about 2 ½ degrees negative camber, which includes the 1 ½ degrees built into the Custom Spindle.

The original upper kingpin attachment uses a ½ inch Whitworth bolt that is drilled through the center and threaded in the head. An oil line attaches to the threaded hole for the “One Shot” lubrication feature. For the 1970-71 Conversion to a Race Car, kingpins were fabricated from 1.0 inch steel rod and this oiling capability was removed. They were cut to the stock length and drilled and tapped at the top with ½ inch UNC threads. A grade 8 bolt secured the top. The bottom was prepared for the shoulder bolt as described above.

New kingpins and bushings were installed in spring 2015. The kingpins were machined as above, from a length of “hardened, tight tolerance, chrome plated” one inch diam. 4140/4142 steel rod from McMaster’s (P/N 6689T12), and bushings, 1 in. ID, 1 5/16 in. OD, 2 in. long purchased from C.E.Gobiel Co., 715 Raymond Ave., St. Paul, MN 55114, (PN BB-1621-32).